There are three main components that are essential to the regular running of an internal combustion engine — air (oxygen), fuel, and an ignition source. Each of these relies on several of its own systems and processes to ensure that they work correctly. One of the many components of the fuel system is the fuel rail pressure sensor, also called the high-pressure sensor. It’s a small yet vital part of today’s direct-injection gasoline engines.

If something were to go wrong with the fuel rail pressure sensor, some of the symptoms you’d experience are pretty similar to what you would deal with in the event of a failed fuel pump. Now, replacing the fuel pump itself is pretty expensive, so it’s always a good idea to rule out the possibility of a faulty fuel rail pressure sensor — especially if you don’t have access to an onboard diagnostics device.

Here’s a guide on all you need to know about the fuel rail pressure sensor and a step-by-step guide on how to replace one on your own.

What Does a Fuel Rail Pressure Sensor Do?

A fuel rail pressure sensor is responsible for regulating fuel pressure in the fuel rail. The fuel rail is the main pipeline that supplies fuel to each cylinder via high-pressure fuel injectors. It’s a critical piece of the fuel system, and the fuel rail pressure sensor controls its activity.

The cylinders in an engine require the right amount of fuel at the right time and optimum pressure. This is governed by the fuel rail pressure sensor that works alongside the ECU, relaying the correct amount of fuel during the intake stroke.

Understandably, when the sensor fails, it can affect the fuel delivery, which then causes issues with the air-fuel ratio. Just like with a bad MAF sensor, the result is improper combustion.

How Does a Fuel Rail Pressure Work?

The fuel rail pressure sensor constantly monitors fuel pressure in the fuel rail. Simply put, it sends this data to the ECU, which changes fuel pressure and injection timing as required. This improves performance and efficiency while also reducing emissions and the amount of unburnt fuel.

While the process sounds relatively straightforward, the sensor’s working is actually quite complex. The body of the pressure sensor comprises a semiconductor and an integrated electric circuit. When fuel passes through the sensor, it applies a mechanical strain on the semiconductor. According to the piezoresistive effect, this results in a change in the material’s electrical resistivity.

The change in electrical resistivity is converted to a digital signal by the integrated circuit and relayed to the ECU.

Where is the Fuel Rail Pressure Sensor Located?

The fuel rail pressure sensor is located on the fuel rail and close to the intake manifold. The easiest way to spot it is to track along the fuel rail and look for the part before the injectors.

What Causes Fuel Rail Pressure Sensor Failure?

Several factors may contribute to the failure of a fuel rail pressure sensor, but the most common include damage from constant exposure to pollutants. Since the fuel that’s continuously flowing through the sensor, any pollutants will cause a buildup over time. The exterior of the sensor is exposed to constant temperature cycles that could cause it to fail as well. This is why using a good quality part makes all the difference.

Your original fuel rail pressure sensor is generally meant to outlive the car. If it fails for whatever reason, you’ll want to get a replacement that is at least equal in quality. Brands such as Bosch offer a wide range of fuel rail pressure sensors like Bosch 0261545071, which are about as good as the Genuine BMW part. Sure, there are decent aftermarket options out there as well, but your mileage using those will vary….potentially by a lot. You can find all of our fuel pressure sensors here.

What Happens When Your Fuel Rail Sensor Goes Out?

If you’ve ever experienced a fuel pump failure, you’ve likely seen some of the problems that a worn-out fuel rail sensor will cause. Some fuel rail sensor failure symptoms include a drop in performance, rough idling or running, and difficulty starting the car. In some cases, it may also send your BMW into limp mode.

Illuminated Check Engine Light

An illuminated check engine light (CEL) is perhaps the first symptom you will experience if the fuel rail pressure sensor goes bad. In any case, the check engine light implies that something is affecting the normal functioning of the engine.

The ECU triggers the light once it finds that the fuel pressure sensor has gone bad or is returning bad data. As a general rule, drop by the mechanics if the light ever blinks on your vehicle’s dashboard.

If you own an OBD2 scanner, you can read the trouble codes yourself.

Difficulty Starting the Engine

Every time you push a button or turn the key to start up your Bimmer, the ECU sends a burst of fuel to be delivered into the cylinders. If the fuel rail sensor is bad, then the correct fuel pressure may not be achieved, resulting in the absence of sufficient fuel required for starting up.

You may find that the engine cranks and maybe even fire up a couple of times before immediately dying. If any consecutive attempts don’t result in a running engine, there’s likely a fueling issue.

Reduced Performance

If your fuel rail pressure sensor is due for replacement, you may also experience a significant drop in power. Every time you step on the accelerator, more fuel and air need to be combusted inside the engine. If the sensor doesn’t register this requirement, the ECU will not send the right amount of fuel for an optimal air-fuel mixture. When this happens, you’ll feel a sudden drop in power delivery.

A lean mixture may also result in a slight increase in fuel efficiency. However, this comes at the cost of excessive engine wear, so you should get it rectified at the earliest.

Poor Fuel Economy

On the flip side, a problem with the fuel rail pressure sensor can force the ECU into misinterpreting how much fuel is required and result in a rich mix. This can cause even more fuel than needed to burn up and reduce fuel efficiency.

Misfiring and Rough Running

As you can see, a problem with the fuel rail pressure sensor can result in either a lean mixture or a rich mixture. In either case, it will result in the inefficient combustion of fuel which can trigger engine knocking and rough running. If the mixture is too lean, it may also result in the engine dying.

Can You Drive With A Bad Fuel Rail Pressure Sensor?

A bad fuel rail pressure sensor could still work, albeit inefficiently. In most cases, it won’t leave you on the side of the road. However, symptoms of a faulty unit will likely get worse with time to the point where you won’t be able to drive your car. If left unattended, a failed fuel rail pressure sensor can lead to constant engine sputtering, and that’s annoying at the very least. Eventually, it might even reach a point where you will no longer be able to keep the engine running for over a few seconds.

If it does come to this, any attempts at forcing the engine to fire up will only cause more damage to the engine’s internals.

How Do You Test a Fuel Rail Pressure Sensor?

The most straightforward method to assess whether there’s something wrong with the fuel rail pressure sensor is to plug an onboard diagnostic tool into your car. The OBD-II device will show you a corresponding diagnostic trouble code (DTC). If you don’t have access to an OBD-II device, you can also bench test the high-pressure sensor with the help of a multimeter.

Disconnect the Fuel Rail Pressure Sensor

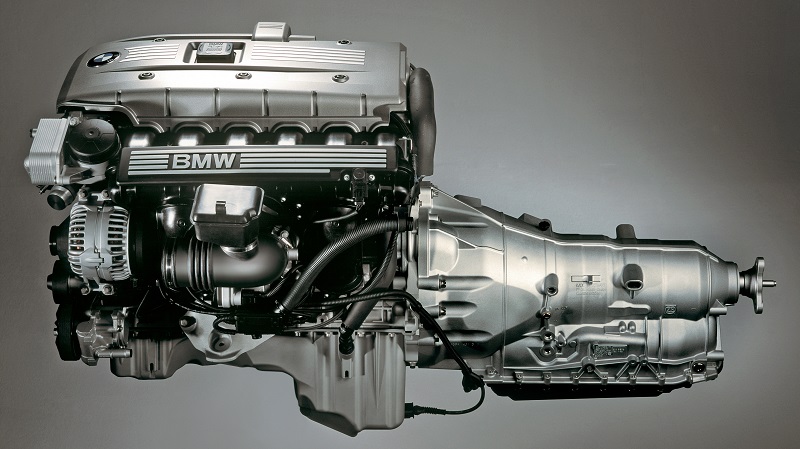

The high-pressure sensor is located under the engine cover on modern-day BMWs. This is a simple process on most models as the engine cover is only mounted at a couple of points. On some other models, like the F10 5-Series, you will also have to disconnect a vacuum hose to remove the engine cover altogether. This isn’t a highly complex job and should only take a couple of minutes.

Once the engine cover and the underlying thermal insulation are removed, disconnect the sensor from the battery. This is a precautionary safety measure that will ensure that the fuel pump does not inject fuel into the fuel rail when you’re working on it.

After this, unfasten the fuel rail pressure sensor from the fuel rail.

Analyze Using the Multultimeter

If you’re not comfortable using a multimeter on your car, it’s best to leave this job to a professional. That being said, use the following information at your own risk.

Once the sensor is disconnected, you should check whether it’s receiving the right amount of voltage to function. You’ll find that the sensor connector has three sets of wires attached to it — typically red, orange, and black — one for sensor power, sensor signal, and ground.

Plug the multimeter onto the BMW by connecting its black cable to the battery’s negative terminal. Meanwhile, the tip of the red probe of the multimeter should be used to test how much voltage is reaching the sensor coupler. You can compare the multimeter readings to the required values in the owner’s manual. If there is a discrepancy, there’s something wrong with the wiring.

Is a Fuel Rail Pressure Sensor Expensive?

A fuel rail pressure sensor is a reasonably inexpensive component and will cost you only about $50-$150, depending on what brand you choose and what BMW you drive. It’s also relatively straightforward to replace one, so labor costs shouldn’t be that expensive either. However, you can replace one on your own in well under an hour, even if you’re not very technically adept.

Buy a Genuine Fuel Rail Pressure Sensor

Here at Bimmers.com, we offer an extensive inventory of genuine, OEM, and quality aftermarket parts for your BMW. We feel that quality has no alternative, especially when it comes to sensitive yet crucial components such as fuel rail pressure sensors. To find the right part for your car, all you need to do is head over to our shop, select your Bimmer from the list, and search for the part you need!

Replaced low fuel rail sensor, still goes into limp mode?

I’m so glad to read this interresting topic and I’d like to read as much as topic from you that deal with the Engine.