By the early ‘90s, BMW had racked up decades of experience producing inline-six engines. This layout helpted get the brand off the ground back in the day, and it also powered some of their best cars up until this point. Needless to say, they were proficient in straight-six motors. So, when they introduced the BMW M60 engine in 1992, it was quite a surprise.

The decision to manufacture an all-new V8 engine came mainly from the direction the industry was headed in — the German manufacturer’s most notable rivals had already begun to produce V8 engines that BMW’s straight-sixes could not keep up with. Enter the BMW M60 engine – the first V8 this manufacturer built since 1965.

However, the M60 had one major flaw that made it almost impossible to own over here. In this guide, we’ll look at how BMW almost lost the U.S. market, if it makes sense to own an M60-powered car in 2022, and what you should look out for if you’re in the market for one.

Technology Behind the BMW M60 Engine

The BMW M60 Engine was designed to power the larger models in the manufacturer’s portfolio and made its debut on the E32 730i and 740i. The inline-six M30 and V12 M70 engines that sold alongside it featured two valves per cylinder and had a more conventional construction.

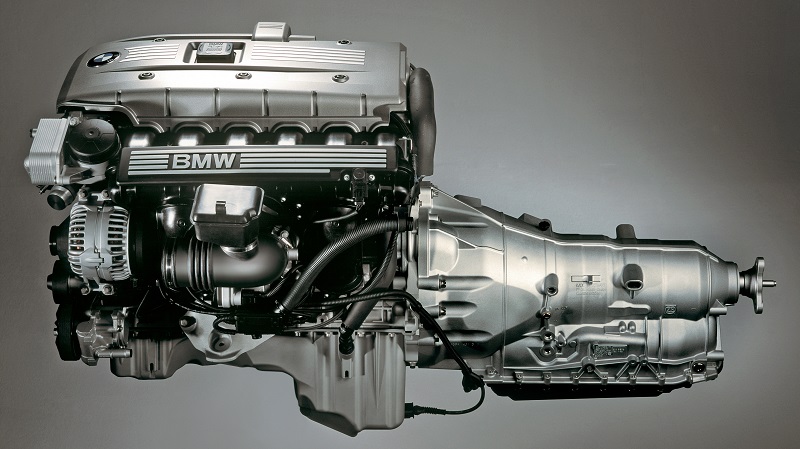

The M60 was strides ahead as it introduced the four-valves per cylinder structure standard across today’s BMW engines. It was a revolutionary introduction to the automaker’s portfolio that it laid the foundation for some remarkable BMW V8 engines that followed, like the manic S63, S65, and N63.

The engine also featured double overhead camshafts, coil-over-plug ignition, and a dual-row timing chain with a self-adjusting tensioner. It was also the first BMW engine to use a “split conrod’ design, where the connecting rods are manufactured as a single piece and then fractured to increase rigidity and get an exact fit.

To keep the engine as light as possible, BMW used aluminum for the engine block and cylinder head, with magnesium for the valve covers. Without its fluids, the engine weighed between 386 lbs and 448 lbs, depending on which version.

ll-Fated From the Start

In an effort to reduce friction and increase wear resistance, BMW decided to use a Nikasil (Nickel infused with silicon carbide) coating instead of the traditional pressed-in steel liners. On paper, this patented process would provide a better seal between the piston and the cylinder while improving longevity. However, in reality, this technology proved to be heavily counterproductive in the North American market.

BMW failed to consider that the fuel in our market at the time had high levels of sulfur, a chemical that had an adverse reaction with the nickel in the cylinder coating. The ensuing reaction would soften the walls of the cylinder and result in an improper seal and, consequently, inadequate compression.

Setting Things Right

Initially, BMW was unaware of why the M60 engines were facing trouble and failing and made multiple efforts to rectify the issue. The Germans first reprogrammed the ECU to reduce how much residual sulfur was left in the cylinder after combustion.

This proved to be ineffective. Then, the manufacturer experimented with different pistons and rings, but the problem remained. BMW then re-fitted several M60 engines with a short-block, but these were also coated with Nikasil and resulted in the same issues.

Largely thanks to this flawed design, BMW phased out the M60 and replaced it with the M62. It was only after doing so that the manufacturer narrowed down the root cause of the issue. An extended warranty was offered to owners, and BMW even replaced multiple engines that were affected. These updated engines used a high-grade aluminum for the cylinder bores, called Alusil, construction that is not susceptible to sulfur damage.

Around the same time, fuel quality in the U.S. significantly improved and didn’t contain as much sulfur. As a result of the countermeasures mentioned above, it’s unlikely that there’s a BMW M60 engine out there today that will still be susceptible to Nikasil-related damage. However, the magnitude of the damage at the time has undoubtedly left this otherwise remarkable engine with a rather tarnished image.

BMW M60 Engine — Available Versions

The BMW M60 engine had a short production run of about four years, from 1992 to 1996. During the time, two iterations of the engine were produced — a 3.0L M60B30 version and a 4.0L M60B40. These variants were produced alongside each other and featured similar construction and design.

M60B30

The M60B30 features 2,997 cc displacement with an 84 mm bore and a 67.6 mm stroke. It had a compression ratio of 10.5:1, with peak output figures of 215 hp at 5,800 rpm and 214 lb-ft of torque at 4,500 rpm. These were relatively humble performance figures even back then, but this was the version of the engine that was oriented towards being smooth and luxurious rather than being a quarter-mile star.

M60B40

The M60B40 was the larger, more performance-oriented version of the BMW M60 engine. It displaced 3,982 cc with an 89 mm bore and 80 mm stroke. With a compression ratio of 10.0:1, peak output figures were rated at 282 hp at 5,800 rpm and 295 lb-ft of torque at 4,500 rpm.

What BMW Cars Had the M60 Engine?

The BMW M60 engine made its debut on the E32 7-Series models but would immediately go on to power the E34 5-Series and the very first BMW 8-Series, the E31.

It also made its way onto non-BMW cars, like the iconic De Tomaso Guarà. Alpina also took the M60B40 engine and tuned it to feature on the BMW Alpina B10 4.0, the B11 4.0, and select models in the B8 4.0 range.

M60B30

The M60B30 powered the BMW 530i (E34) from 1992 to 1995, BMW 730i (E32) from 1992 to 1994, and the BMW 730i (E38) from 1994 to 1996.

M60B40

The M60B40 was the more popular iteration of the engine and made its way onto more models. These included the BMW 540i (E34) from 1993 to 1995, BMW 740i (E32) from 1992 to 1994, BMW 740i (E38) from 1994 to 1996, and the BMW 840i (E31) from 1992 to 1996.

Is the BMW M60 Engine Reliable?

The BMW M60 engine is a reliable piece of engineering for the most part. The high sulfur fuel in the U.S. did cause some serious issues when the engine was first introduced, but BMW rectified the engine’s design eventually, and fuel quality got significantly better as well.

However, you should know that even the most recent iterations of the engine produced are nearly 25 years old. Most examples you’ll find on the pre-owned market will likely have done hundreds of thousands of miles, and even low-mileage engines are bound to require some work to keep them running smoothly.

Is the BMW M60 a Good Engine?

The BMW M60 has flaws, but it’s an excellent example of the kind of engines that made the German manufacturer the powerhouse it is today.

If you’re looking to enjoy a trouble-free ownership experience or heaps of performance, this is not the engine for you. However, if you want to revel in the luxury of yesteryear, a BMW M60-powered car may just be exactly what you’re looking for.

BMW M60 Engine — Pre-Purchase Inspection and Common Problems

The BMW M60 engine was a considerable step ahead in design and construction for the German manufacturer when it first came out. Despite its shortcomings, it was a relatively reliable engine. However, considering its age, some components are bound to wear out and require replacement.

If you’re interested in buying a pre-owned M60-powered car, it’s vital that you get your hands on one that’s in relatively good shape and won’t cost you a lot of money to keep in running order.

Nikasil Bore Coating Problem

The first thing to check is whether the Nikasil bore coating mentioned above has affected the engine. Nikasil, a combination of aluminum, nickel, and silicone, proved somewhat problematic to the BMW M60 engine.

When the engine was introduced in our market, the fuel we had access to was extremely high in sulfur content. The nickel in the engine reacted adversely with the sulfur in the fuel and resulted in significant damage to the cylinder walls.

As a result, the engines could not produce enough compression, resulting in improper combustion and, in more severe cases, a seized engine. BMW tried to resolve the issue in multiple ways and ultimately replaced the Nikasil-coated parts with a high-grade aluminum called Alusil that wasn’t susceptible to sulfur damage.

Additionally, it also offered an extended warranty of 6 years and 100,000 miles on the engine and replaced affected units for free.

It’s unlikely that one of the earlier M60 engines is still running on the stock cylinders today; one of the previous owners is bound to have had it replaced under warranty or otherwise.

Nevertheless, this is not a matter of grave concern since fuel quality has improved significantly over the last couple of decades. For reference, the government mandated that sulfur content in fuel was to be capped at 300 ppm by 2004. Today, that number is down to 30 ppm.

If you want to check whether the engine on your car has been replaced, check the right-hand side of the engine block for the casting numbers. Here is the list of casting numbers you will see and the corresponding engine construction:

- Nikasil M60B30 – 1 725 970 or 1 741 212

- Nikasil M60B40 – 1 725 963 or 1 742 998

- Alusil M60B30 – 1 745 871

- Alusil M60B40 – 1 745 872

Timing Chain Guide Failure

A timing chain guide failure is one of the more common issues you’re likely to deal with on a BMW M60 engine.

The timing chain on the M60 comprises one tensioner that uses guide rails. Both these components are susceptible to failure on this BMW engine. Since the timing chain is metal, the guides are made of a plastic composite to avoid metal-on-metal contact.

Unsurprisingly, this plastic component will wear out in time. Proper maintenance should be able to get you past the 100,000-mile mark, but don’t be surprised if they fail prematurely. Check for cracks in the guides when you’re getting your car serviced. If there is a complete failure, it can throw the timing chain off the guide and result in catastrophic damage.

If the timing chain or the guides are starting to wear out, you should hear a rattling or whining sound from the engine, accompanied by an illuminated check engine light on your dashboard.

Cooling System Issues

The cooling system that worked alongside the BMW M60 engine included multiple components, like the viscous fan, expansion bottle, burst hose, coolant hoses, and the radiator. Considering the age of all these parts, you should be wary of impending failure.

The BMW M60 engine uses a radiator that sits within a plastic housing. This housing is prone to cracking or breaking at the top, where the coolant hose is connected. Unfortunately, you cannot replace the housing alone, and any damage to it will require the entire radiator. You should check the condition of the housing and the radiator before purchasing an M60-powered car.

Another weak point in the cooling system is the expansion tank that may crack, resulting in excessive coolant leaking onto the engine bay. If this happens, you’ll see thick clouds of smoke from the car’s front end — a tell-tale sign of a coolant leak.

Apart from the issues mentioned above, it’s best to check the entire cooling system for any weak points that may be due for a replacement soon.

Should You Buy An M60-powered BMW Today?

Back in the day, the BMW M60 engine powered some of the most luxurious models the German manufacturer had to offer. These cars, even by today’s standards, can be pretty desirable. The only significant chink in the engine’s otherwise impenetrable armor is the Niksail bore coating issue.

However, as we mentioned above, this is not a concern anymore. In fact, most of the expenses you’ll have with a decently maintained M60 engine will be with regular wear and tear from the extensive mileage these engines have covered. That’s where we can help. Here at Bimmers.com, we offer one of the largest catalogs of Genuine BMW, OEM and quality aftermarket parts. Check out our store and chances are you’ll find what you’re looking for!