When it comes to taking care of our vehicles, we often focus on regular maintenance, fluid checks, and repairs. One crucial aspect that often goes unnoticed is the use of break-in engine oil during the early stages of a vehicle’s life. In this short guide, we will explore the purpose of break-in engine oil and shed light on its vital role in ensuring the long-term health and performance of your engine.

What is Break-In Engine Oil?

Break-in engine oil, also known as running-in oil or break-in period oil, is a specialized type of lubricant used during the initial break-in phase of a new or rebuilt engine. It is formulated to meet the specific requirements of this critical period and differs from regular engine oil in its composition and properties.

Break-in engine oil is designed to provide optimal lubrication and protection to the engine components during the break-in process. It typically contains unique additives and a specific blend of base oils that help facilitate the wear-in of various moving parts, such as piston rings, cylinder walls, and bearings.

The additives in break-in oil serve several purposes. They help to promote controlled and gradual wear, allowing the mating surfaces of the engine components to establish proper contact and form a reliable seal. This controlled wear-in process is crucial for achieving optimal compression, minimizing oil consumption, and ensuring long-term engine performance.

In addition to aiding in wear-in, break-in engine oil also offers enhanced lubrication properties. It is formulated to reduce friction and minimize metal-to-metal contact, providing a protective barrier between engine components. This helps to prevent excessive wear and potential damage during the break-in period.

Break-in oil may also contain additives that assist with heat dissipation. New engines tend to generate more heat during the break-in phase due to increased friction, and these additives aid in keeping the engine temperature regulated, preventing overheating and potential thermal stress.

Furthermore, break-in engine oil often includes detergents and dispersants that help trap and suspend metal particles and debris that are generated as the engine components wear-in. By keeping these contaminants in suspension, break-in oil helps prevent them from causing further damage and maintains a cleaner engine environment.

It is important to note that break-in engine oil is typically intended for temporary use during the break-in period, which can vary depending on the manufacturer’s recommendations. Once the break-in process is complete, it is advisable to switch to a regular engine oil that meets the specifications outlined by the vehicle manufacturer.

Is Break-In Oil Necessary These Days?

The use of break-in oil in modern engines is a topic of debate among automotive experts and manufacturers. While break-in oil was traditionally considered essential for properly breaking in new or rebuilt engines, advancements in engine technology and manufacturing processes have led some manufacturers to claim that it is no longer necessary.

Modern engines often come from the factory with high-quality lubricants that have undergone extensive testing and meet specific requirements for optimal performance and longevity. These oils are designed to provide sufficient lubrication and protection during the initial stages of the engine’s life.

Additionally, advancements in engine manufacturing, such as improved machining techniques, surface treatments, and tighter tolerances, have reduced the need for an extended break-in period. Many modern engines undergo a pre-conditioning process at the factory, where they are run briefly to help seat the components and ensure proper initial operation.

However, it’s important to note that the specific recommendations for break-in procedures and oil usage can still vary between manufacturers and engine types. Some manufacturers may still recommend the use of break-in oil for certain high-performance engines or specific applications. At the end of the day, it is a matter of personal preference, especially with rebuilt engines.

Motul 10W-40 Break-In Oil

Motul 10W-40 Break-In Oil is a specialized lubricant designed to facilitate the break-in process of a new or rebuilt engine. Engine break-in is a critical stage where the various moving components of an engine, such as pistons, rings, and bearings, establish their proper fit and create a seal. During this phase, it is essential to provide adequate lubrication to minimize friction, heat, and wear, while allowing the components to gradually adapt to each other.

Motul Break-In Oil is formulated with specific additives and base oils that offer exceptional protection and lubrication properties during the critical break-in period. The oil is designed to enhance the formation and bedding-in of piston rings, allowing them to properly seat against the cylinder walls. This process ensures optimal compression and oil control, contributing to improved engine performance and longevity.

Get Motul 10W-40 Break-In Oil!

How to Use Break In Oil?

Using break-in engine oil properly during the break-in period of a new or rebuilt engine is essential to ensure its effectiveness. Here are some general guidelines to follow when using break-in engine oil:

Consult the Manufacturer’s Recommendations: The first step is to refer to the vehicle manufacturer’s recommendations or the instructions provided by the engine builder. These guidelines will outline the specific break-in procedure, including the recommended break-in oil to use and the duration of the break-in period.

Drain the Initial Factory Fill: If your engine comes with an initial factory fill of oil, it is advisable to drain it before adding the break-in oil. The factory fill oil may contain residues or additives that are not compatible with the break-in process.

Choose the Correct Break-In Engine Oil: Select a high-quality break-in engine oil that meets the specifications outlined by the manufacturer or engine builder. These oils are specifically designed for the break-in phase and contain the necessary additives for optimal lubrication and component wear-in.

Follow the Oil Change Interval: During the break-in period, it is common to change the oil and filter more frequently than usual. The manufacturer’s guidelines will specify the recommended oil change intervals during this phase. It is crucial to adhere to these intervals to maintain the effectiveness of the break-in oil.

Avoid Extreme Operating Conditions: During the break-in period, it is generally advised to avoid subjecting the engine to extreme operating conditions, such as high speeds, heavy loads, or prolonged idling. These conditions can put excessive stress on the engine components and hinder the proper wear-in process.

Gradually Increase RPM and Load: To allow the engine components to wear-in gradually, start with gentle driving and gradually increase the engine RPM and load over time. This progressive approach helps establish optimal contact between mating surfaces and promotes a proper seal.

Monitor Oil Consumption and Performance: Keep an eye on oil consumption and engine performance during the break-in period. It is normal for some oil consumption to occur during this phase, but excessive consumption or abnormal performance should be addressed with a professional mechanic.

Remember, the specific steps and procedures for using break-in engine oil can vary depending on the engine type, manufacturer recommendations, and other factors. Always refer to the manufacturer’s guidelines and follow the instructions provided by the engine builder for the best results.

Get Quality Break-In Engine Oil at Bimmers.com

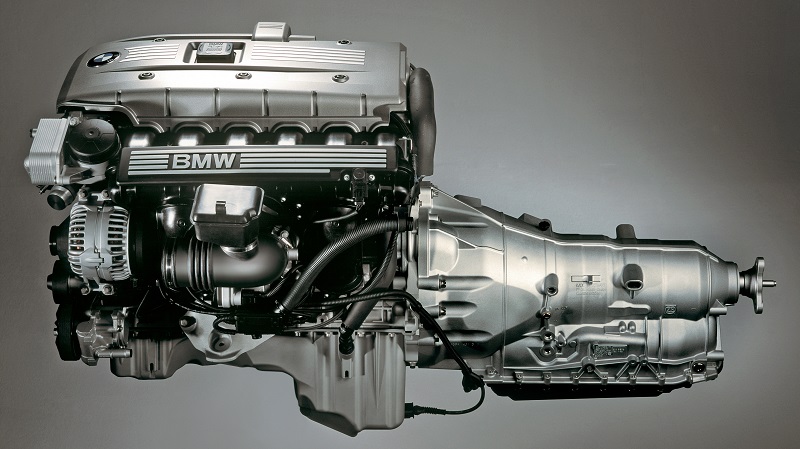

Here at Bimmers.com, we offer a wide range of high-quality lubricants, including break-in engine oils. Head over to our store, select your vehicle and find a lubricant that is perfect for your BMW. Choose between genuine BMW, Motul, and other brands.