The BMW E46, the fourth generation of the popular 3-Series, is one of the more iconic cars the German manufacturer has produced. A decade and a half since the last E46 3-Series left the factory, it grown to become a favorite amongst enthusiasts and lives on as a collectible classic.

Over the years, the E46 has proven to be an excellent platform for building a more dedicated performance machine. Whether a track car or a drift car, you’ll find several tuners and various aftermarket parts in the market.

That said, there is one undeniable chink in the E46’s otherwise impressive armor — its subframe. Rear subframe issues are notoriously common on the BMW E46 models, and if you’ve owned them long enough, you’re bound to run into issues with them. Even BMW acknowledged this was a problem and recalled cars affected by the issue.

If you own a fourth-generation BMW 3-Series, an E46 subframe reinforcement is something you should consider. There are a couple of ways you can go about doing this, each better suited for different scenarios. This guide covers everything you need to know about the process.

What Year E46 Have Subframe Issues?

By the German manufacturer’s own admission, every model year of the BMW E46 faces the risk of subframe issues. In 2006, a class action lawsuit was filed against the company claiming that it was aware of problems with the rear subframe and mounting points. Not only that, but they failed to notify customers of the issue.

It took three years for the involved parties to come to a settlement. In 2009, BMW North America released a statement saying that: “BMW has agreed to a proposed settlement of a class action lawsuit concerning the Sub-Frame structures on 3 Series (“E46”) models produced from 1999 through 2006. Under rare conditions, the attachment points of the Sub-Frame may develop a fracture or crack.

BMW has prepared an inspection, approved repair procedure, and reimbursement policy in keeping with the terms of the proposed class settlement. Details will be forthcoming, pending the court’s final approval of the proposed class settlement. In advance of the final settlement, BMW customers with questions should visit www.E46subframeclassactionsettlement.com.”

Some of the cars have been fixed over the years. If subframe reinforcement was carried out on your BMW E46, you should have nothing to worry about. However, several owners out there did not benefit from the manufacturer’s offer. If you’re one of them, you’ll have to figure this out yourself. BMW offered to make amends only for a limited duration, and the link mentioned above is no longer live.

That said, we have all the information you’ll need on how to do this on your own, so it shouldn’t be too much of a hassle.

Which Part of the E46 Subframe Is Most Prone to Failure?

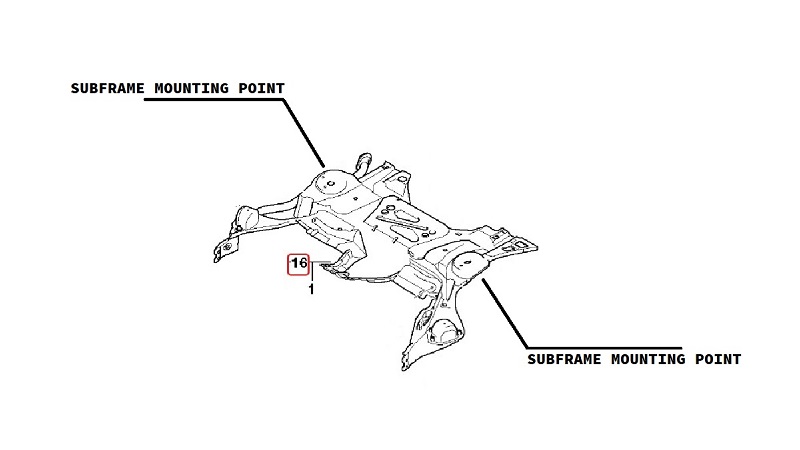

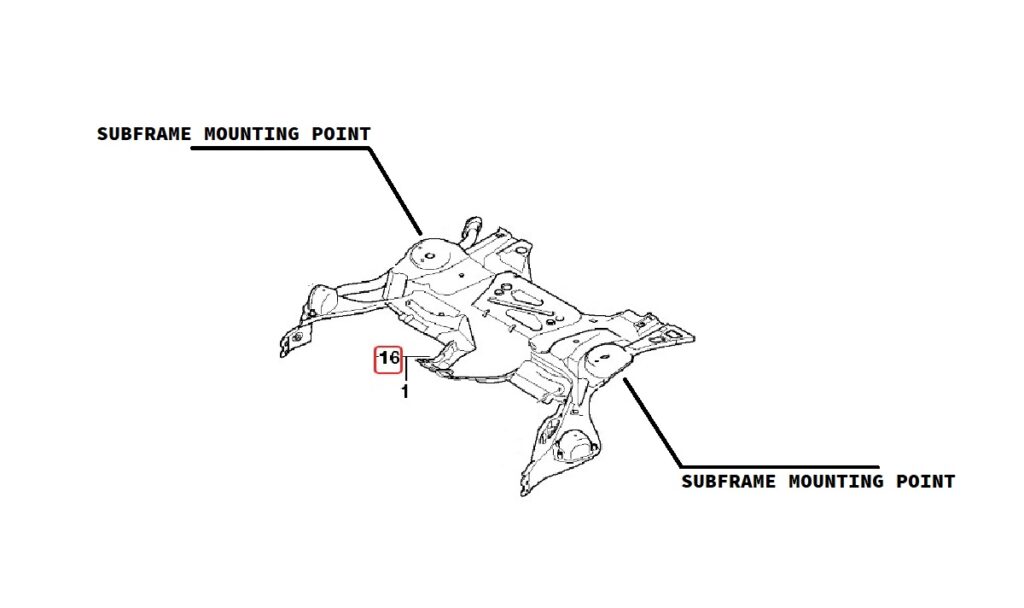

The rear subframe and floor are most prone to failure on the BMW E46 models. The first area you should start noticing any cracks is at the subframe mounts. These cracks develop due to the constant torsional stress from the rear differential. It’s important to know that a crack in the subframe mounting isn’t a sudden occurrence but a gradual result of repeated stress cycles.

This is why an E46 subframe reinforcement is crucial. Strengthening the area will prolong, and might even prevent, the rear subframe from failing.

How Do You Reinforce a Subframe?

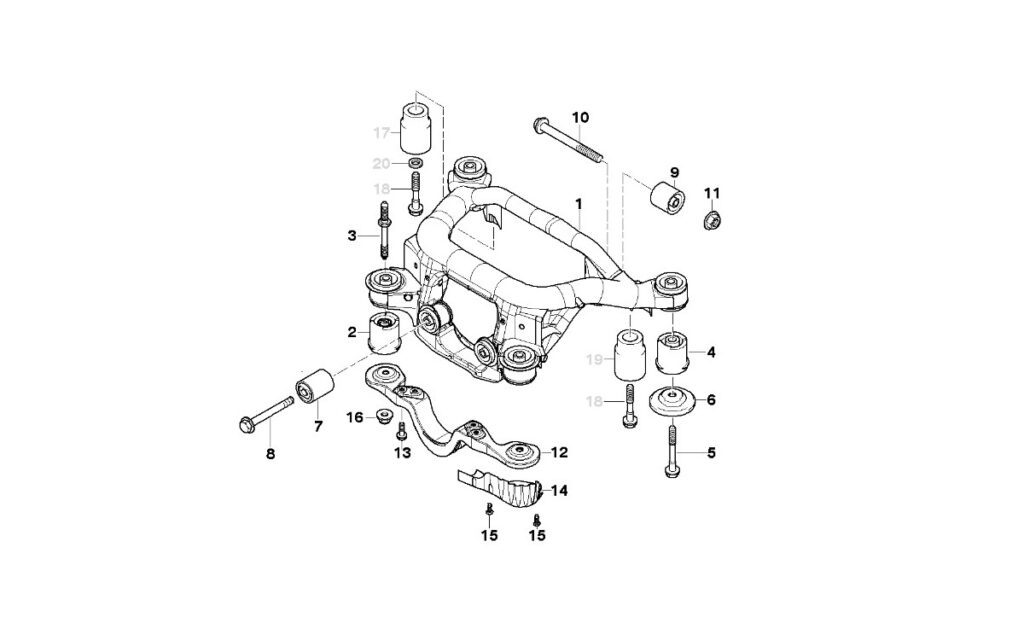

There are a couple of ways to perform an E46 subframe reinforcement. The first way involves injecting foam between the two layers of the rear floor. The other is a bit more permanent and involves the use of reinforcement plates at the mounting points where you bolt on the subframe bushings. Understanding the construction of the rear subframe and floor will help you decide which method is better.

The two steel sheet layers that make up the rear floor of the E46 have a small gap between them, reducing structural rigidity. BMW tried to counteract this by spot welding a reinforcement brace to the front two mounting points of the subframe. However, as you may have predicted, this only transfers the torsional stress to the rear two mounting points, which are usually the first to give way.

BMW then tried to resolve this issue by injecting foam into the gap between the two layers. It was the solution that the company offered to all its customers.

Should You Choose Foam or Metal Plates for Your E46 Subframe Reinforcement?

The foam that BMW injected between the rear floor sheets of the E46 hardens and reduces the rotational stress on the subframe mounts. As a result, this method did offer some degree of resolve. But, it does have its drawbacks. For starters, working on this section of the car can be problematic. The vapors from the burning foam are incredibly hazardous. Welding around it is difficult. This makes suspension, powertrain, and chassis work troublesome, even for a skilled technician.

Additionally, the foam method is ineffective in cases where the mounts or other parts of the subframe have already started to crack.

The recommended and more effective method is to opt for metal reinforcement plates. There are numerous aftermarket E46 subframe reinforcement kits that feature such plates. On the other hand, some owners use epoxy glue or other adhesives, welding them on should prove more reliable. This method works even on E46 models with mounting points that have already begun to develop small cracks.

How Much Does It Cost to Repair an E46 Subframe?

An E46 subframe reinforcement can cost around $1,000 in total. it all depends on which method you opt for and the kind of aftermarket components you decide to use. On the other hand, replacing the entire subframe can cost close to $5,000, and that’s if you can even find a new subframe to buy. Afterall, some of these cars are more than 20 years old by now. Finding new structural parts can be tricky.

While the subframe on a well-maintained E46 should last over 100,000 miles, there have been instances where cracks have developed as early as 50,000 miles. Inspecting the subframe completely will require you to drop it from the rest of the chassis, so it’s best to carry one out when work is done to neighboring components like the rear axle or suspension.

Get the Best Parts for Your BMW E46

The BMW E46 has grown into a cult classic simply because it has so much potential. If looked after and driven well, it shouldn’t give you any issues. If you’ve found a car that you really like, it pays to check the subframe. That way you’ll know if you need to think about E46 subframe reinforcement.

At Bimmers.com, you can find an extensive list of BMW E46 parts, from entire kits to mounts, bushings, and bolts. To see all the options you can select from, head to the website and simply enter the year and model of your vehicle. You’ll be shown a comprehensive list of parts that are a perfect fit for your ride.